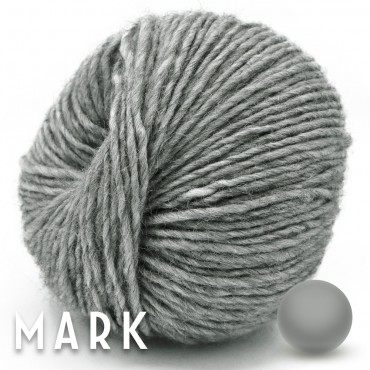

Ball of 90% SUPERWASH Merino 10% Silk. Extrafine wool mixed with Tussah silk. Suitable for babies creations. Weight 50 grams Length about 120 Meters. We suggest you to use: Knitting needles 4-5 Hook 3.5-4.5. [P.ta 6023]

0 prodotti 0

Your cart is empty

Filter By

Colore

Colore

baby wool

Merino Wool and Wool Blends

Types of Wool and Uses

Choosing the composition of the yarn to use for a project is extremely important. Each type of wool has its characteristics, and it's important to know them, even superficially, to make an informed choice.

Merino Wool

Also known as Merino wool, Merino wool is named after the animal that provides its fleece to make it. Originally from Spain, today the highest production and especially quality generally recognized as superior, we find it on the other side of the world. In Australia!

However, Merino wool also has intrinsic characteristics that need to be understood, which are related to the length and thickness of the fiber: the finer and longer the fiber, the more precious it is. This is how we can explain the various terms: fine Merino wool and extrafine Merino wool, where the second one is thinner and longer is the highest level of Merino available on the market.

Why does wool itch?

This question is answered by referring back to the previous paragraph. When wools are fine and curly like Merino wool, there are no "flaws" in the fiber, like "spikes" that protrude from the fiber itself. These tiny and invisible spikes to the human eye are precisely what produce that annoying sensation on the skin. Naturally, the annoyance should not be confused with an allergy. If one is allergic to wool, in the clinical sense of the word, then one will have to choose cotton or a synthetic yarn.

Virgin Wool

When we talk about virgin wool, we are referring to a product that is made up of wool that is neither regenerated nor derived from other processes. Virgin wool is shearing wool, therefore wool that comes directly from shearing the animal.

Carded Wool

When we talk about carded wool, we refer to wool that does not go through the entire production process of wools but stops at carding. This process, which historically was done by hand, is used to remove impurities present in the fiber. Carding is the process that comes before combing, so carded wool does not undergo those treatments typical of twisted wool, remaining so to speak "raw". Usually, carded wool is very used for making fabrics where the subsequent processes are not necessary.

Combed Wool

Combed wool, on the other hand, is the wool that continues the process after carding where the fibers are laid out and twisted and then used both in knitting (wool yarns) and for the textile industry.

Bulky Wool

After the wool preparation processes, it is possible to twist multiple threads together to create greater thicknesses. The thickness in yarns is identified through the count, which is the ratio between the weight of the product and its length, therefore it goes without saying that the higher this ratio, the thinner the thread will be. This ratio can also be translated into a final count and also in this case the lower the value, the thicker the yarn.

Types of Wool

The most well-known types of wool besides Merino wool include cashmere, mohair wool, alpaca wool, angora wool, llama wool, camel wool, etc. There are naturally many other lesser-known or very precious animal-derived wools such as Vicuña wool, typical of the Andean countries in South America, which at the time of writing reaches the wholesale price of 1700 dollars per Kg!

Color Shades

Wool, like any animal fiber, can be dyed and therefore can be colored with dyeing processes in any shade. In variegated colors, therefore when we see yarns with multiple shades, printing techniques are applied that fix the color on the fiber to make them multicolored.

Wool Blends

In modern times, the use of blended wools is increasingly common. Wool blend or mixed wool is the result of a wool base with synthetic products such as acrylic, acrylic microfiber, polyamide, polyester, etc., based on the final use for which the product is intended. Even quality wool blend can fall among those commonly called Baby Wool. With this improper name, wools intended also for clothing for the little ones are indicated.

How to prevent wool from pilling?

This annoying yet very normal event on wools is called Pilling. We could distinguish two different types of Pilling: the pilling that we will call "good" and the "bad" pilling, a bit like cholesterol.

Good pilling occurs when the shorter fibers detach from the fiber bed and with movement, these small lumps of fiber are formed. It’s a typical occurrence of less twisted wools and not necessarily of poor quality, but which release these shorter fibers which, in the case of good pilling, will not reform after a few washes.

Bad pilling, on the other hand, is typical of synthetic yarns and tends to get entangled in the fiber, making the garment look optically old and difficult to recover. Removing bad pilling bobbles is very difficult.

One practice that should NEVER be done in case of pilling is using scissors or even worse, cheap gadgets that tend to cut the fiber. This does not allow the fiber to be completely purged and can cause the unpleasant effect to reappear over time.

Curiosities

We are always looking for yarns on sale, cheap yarns or even free yarns, but we must not forget that even if we talk about yarns (on sale, cheap, free) we should always evaluate some important details: composition and origin. Many shops call 100% acrylic yarns maybe from Turkish or Chinese origin wool, what you find from Tessiland is 100% wool Made in Italy.

How much wool is needed to make a blanket?

One of the most frequent questions to our support center is this! And we refer to an article on our blog to see in detail recommendations and quantities.

What is Microfiber?

Microfiber has nothing to do with wool. Moreover, microfiber is an adjective and it determines a quality of a fiber. To learn more read the article on our blog.

What is done with the wool of black sheep

Typical of the Sardinian sheep, the black sheep a few years ago was quite sought after by designers who made it the star of their collections. A naturally colored wool that was proposed as a natural color. Then things changed and today unfortunately the wool of the black sheep is much less requested and is used in textiles to be mixed with white wool due to its low cost.

How wool is made

The process for the production of wool is long and complex. Simplifying it a lot and without going too much into detail and simplifying the terminology as much as possible, the phases are:

- Shearing: the collection of the animal's hair which, among other things, should be done at specific times of the year depending on the breed and the place where the animal lives.

- Shearing: Operation of separating the animal's fleece with manual or mechanical clippers. ...

- Sorting: is a first selection of the fiber discarding the unusable material

- Washing: an initial washing is needed to remove impurities from the fiber

- Drying: the fiber is dried using particular processes

- Opening and Beating: in this phase, the fibers are disentangled and aligned to prepare for carding.

- Carding/Combing: the phase where the disentangling ends, making the fibers ready for combing, which is precisely the process in which the fibers are aligned, so to speak.

- Spinning: where the fiber is transformed into continuous thread.

- Doubling and Twisting: is the phase in which the continuous thread is paired with other threads to give life to the actual yarn.

Let's see one of the most beautiful wools on the market: